Built to last

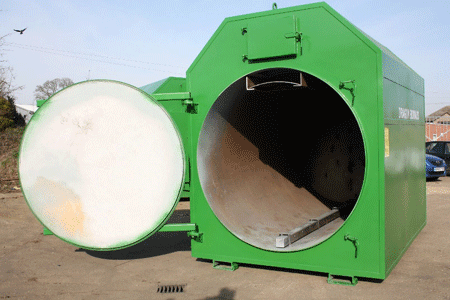

The furnace walls of the Dragon boiler are thicker than all our competitors and we are the only British company to build our own biomass boilers using boiler plate. Boiler plate is made to expand and contract with the heat stresses inside the furnace. This creates longevity of the boiler. Many of the Dragons built in the seventies are still working now. The cylindrical shape of the furnace is proven to be the most effective design for steel that has to withstand more than 1100 degrees of heat during a burn cycle.

The furnace cylinder is well insulated using rock-wool to reduce heat loss.

The door is built using cement designed to withstand temperatures of up to 1600 degrees and then heavily insulated. This has been proved over the decades to be easily the most durable way of making a furnace door.

The heat exchanger tubes are seamless which reduces the likelihood of irreparable damage to the boiler during it’s lifetime.

The weight of the boiler also gives an indication of the amount of material used and therefore the quality of the Dragon.

All these factors add up to the Dragon being the most likely to withstand the next 20 plus years of use.

Points to consider when choosing your boiler;

Furnace size; Decide which fuel you will primarily be burning, ie straw, wood, waste wood. If it is likely to be a combination of fuels, then choose the largest of these ie round bales and virgin wood.

How many kW do you need; Look at your existing heat requirements and decide what else you would like to heat.

The easiest way to check this is to look at your existing boiler (1 kW = 3412 btu)

Measure the property in cubic metres, divide by 31. This equals your kilowatt requirement.

If you have any doubt, call us and we will calculate your requirement or visit you on site.

Call us to discuss and we can help to calculate how many kilowatts are required for workshops, grain driers etc

How many times a day do you want to load the boiler; Ideally, we would spec a boiler so that you only load it once a day. Some fuels burn quickly and will need loading more often for example, pallets.

The addition of an accumulator tank into your system will greatly reduce the number of times you will need to load.

During cold weather, the boiler may need loading twice a day.Some people have a heat requirement and a waste fuel that they want to burn without worrying about the efficiencies of the boiler. For these people, we have a low cost option with the Single Pass range of boilers. We still use boiler plate, however there is no heat exchanger and relatively low smoke control.